-

▶ 具有极好的低温耐受性能

▶ 改善了脱模/模具污染性能与Viton®GF相比

▶ 改善了模流,减少了剪切灵敏度较低,挤出机模具膨胀率较低~65穆尼FKM

▶ 表现出相似的热量、流体和低温与Viton®GF相比

▶ 具有优异的抗压缩凝固性能

▶ 表现出相似的热量、流体和低温与Viton®GF相比

静态密封:

动态密封:

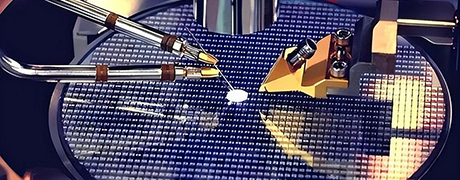

晶圆传输:

Chamber seals

Flange NW/KF centering o-rings Gaskets

Fitting and union seals

Valve seals

Door seals

Lid seals

Bonded slit valve doorsEnd effector pads

Vacuum suction parts

Property

Value

ASTM

Material Type

GF

Perfluor

Colour

Black

Indoor

Hardness: (Shore A)

74

D2240

Tensile Strength (MPa)

14.8

D412

Elongation at break (%)

279

D412

100% Modulus (MPa)

5.78

D412

Compression Set (%):

70 hrs @ 204°C25

D395

Minimum Operating

Temperature-15℃

Indoor

Maximum Operating

Temperature230℃

Indoor

Coefficient of Thermal

Expansion (um/M°C)216

Indoor

▶ Lon implant

▶ Dry ashing

▶ CVD

▶ Deposition

▶ Wet etch

▶ PVD

▶ Oxidation(LPCVD) -

-

2024-05-15 FF770.pdf

끂2 162.73 KB

-